Amorphous metals or “Glassy metals” are typically an alloy of two or more metals such as titanium, magnesium, lanthanum, zirconium, palladium, iron or copper. While most formed metals have a brittle crystalline structure, alloys of these metals can be formed in a manner that gives them a non-crystalline structure at room temperatures. The alloys are formed by rapidly heating and cooling the materials so that they do not have sufficient time to form a crystalline structure and are therefore more “glass like” in their structure. However, unlike plate glass, they are metallic and therefore conductive. The non-crystalline structure of these alloys results in a very strong, light weight, scratch resistant material ideal for cell phone cases and watch components.

IWT’s extensive experience with titanium along with our capacitor discharge technologies, made us the ideal partner for research into the commercial production of bulk glassy metal “BGM” products. IWT designed and manufactured two systems for the formation of BGMs for Caltech. The first was a research system for heating BMGs to form small molded components. The second was a larger energy system with innovative pneumatic ram to form large BMGs. Feel free to contact IWT to discuss these and other innovative capacitor discharge uses.

CALTECH UNIT 1 – RESEARCH

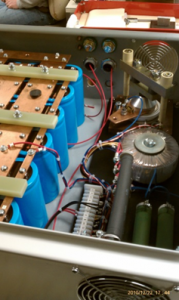

CALTECH UNIT 2 – BGM PRODUCTION